Description

|

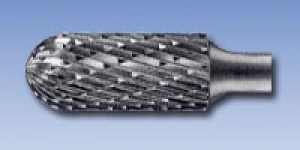

PFERD tungsten carbide burrs are designed for matching materials of virtually any strength.

Their superior performance reflects an optimum combination of key parameters such as shape, number of flutes, spiral angle, rake angle and concentricity. |

Cylindrical burr with radius end according to DIN 8032 with cut conforming to DIN 8033. Combination of cylindrical and ball-shaped geometries.

Technical information

| Outer dia. | 10 mm |

| Width | 25 mm |

| Shank dia. | 6 mm |

| Overall length | 65 mm |

| Cut | 3 PLUS |

| Packing unit | 1 pcs |

Materials that can be worked:

- Hard aluminium alloys

- High-temperature-resistant materials

- Cobalt-based alloys

- Other non-ferrous metals

- Nickel-based alloys (e. g. Inconell and Hasteloy)

- Stainless steel (INOX)

- Cast iron

- Grey/nodular cast iron (GG/GJL, GGG/GJS)

- Annealed cast iron

- Black cast iron (GTS, GJMB)

- White annealed cast iron (GTW, GJMW)

- Steel, cast steel

- Hardened, heat-treated steels over 1,200 N/mm2 (over 38 HRC)

- Case-hardened steels

- Tool steels

- Steel

- Steels up to 1,200 N/mm² (< 38 HRC)

- Cast steel

Applications:

- Milling out

- Leveling

- Deburring

- Cutting out holes

- Surface work

- Milling

- Weld dressing

Drive types:

- Flexible shaft drive

- Straight grinder

- Stationary machines

- Robot applications

- Machine tool

Made in Germany

Reviews

There are no reviews yet.